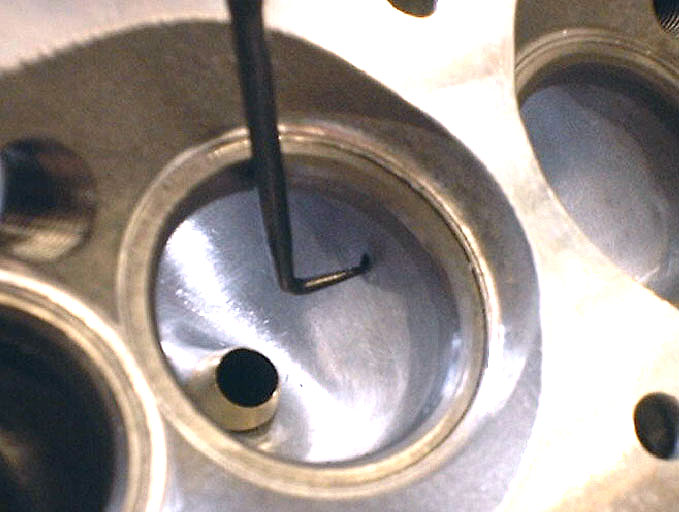

Pierce MSX Cross flow Cylinder Head Update. On the 18th of January, 2003, I posted on the MG BBS forums, an “article” of sorts outlining our initial experience with Pierce Manifold’s MSX cylinder head offering. This BBS post was not intended to be an end-all thesis on the MSX head, but instead a general outline of how cylinder heads are developed and modified by persons doing that sort of work. Since that time, we’ve done many more MSX heads and spent countless hours’ flow testing and developing them for the greatest performance possible. It is safe to say that we reached the point of diminishing returns some years back and have been pushing these castings to the razors edge for the last couple years or more. To that end, I am stating here and now that we have reached the limit of performance available from these heads within 99.9% and will no longer be porting them. Most recently, we began work on an MSX casting that had suffered from very serious core shift of the water jacket cores inside the head. Unfortunately this malady was invisible from outside view and our past successes had left us complacent as to the need for checking port wall thickness prior to beginning our work. After removing less than .040” from an exhaust port wall, a small piece of casting broke free, creating a hole in the port wall itself. Further investigation showed that the water jacket cores had shifted sideways, leaving two inlet ports with exceedingly thin walls and two with much thicker walls in the areas where they could readily be measured. In order to satisfy our customer, we purchased another head at our own expense. The new head was thoroughly checked for casting integrity by means of sonic testing and by physical thickness checks where possible. This new casting was fortunately very sound and correct and has since proven successful. Our attitudes about these heads however, have only worsened as a result of this happening and we felt it was time the MG community be given an update. Looking back to the year 2003 BBS post, it is clear our opinion of these heads was not entirely one of enthusiasm. We have felt since the first head we received (and maintain the feeling still), that these heads do not represent good value for their cost. Our feeling was that these heads were simple copies of the Derrington items without any kind of development work and in fact, any changes seemed to have been made more for ease of foundry work than for any significant performance increase. Five years later, our feelings about these heads have not changed. Early this winter, we did a dyno development project which included testing of many types of cylinder head castings for the MGB engine, in various states of preparation. We tested stock style heads with simple valve jobs, modified iron heads of various casting types and MSX cross flow heads, both stock and modified. Our dyno testing confirmed our flow bench findings and customer feedback, the MSX heads were not great performers out of the box. The stock MSX head and twin SU manifold combination did not improve peak torque or horsepower numbers. The stock MSX cylinder head and manifold combination did increase very low RPM torque and horsepower numbers, but did not do well above these lower RPM points. While we feel this increase in the low end is very valuable, we also feel it’s a shame the stock MSX head and manifold did not increase the performance above that point. Only with our fully ported cylinder head and custom fabricated SU inlet manifold, did we begin to find meaningful power increases above similarly prepared Siamesed, cast iron heads at RPM’s above 3,000. For what it’s worth, past experience has shown the twin DCOE manifold and carburetor setup as superior, but we did not have time during our early-winter test session to make direct comparisons. Either way, our testing of both stock and custom SU manifold setups on both stock and modified cylinder heads during our latest session supports the notion that you can’t fix cylinder head problems with a manifold, there is a built in limitation and there is no getting around that fact. For us, the lack of performance we found was not surprising, for the average consumer who has read glowing sales literature however, this might come as a shock. The truth is, these heads do not possess the correct port sizing, shaping, or combustion chamber contours necessary to properly deliver, combust, or rid the engine of the gasses used to make power. The inlet ports are very small and simply choke off at higher RPM’s. The combustion chambers do act as a semi-efficient space for combustion to occur, but are not shaped to best allow flow into or out of them. Any mild improvements to the exhaust ports over a stock iron head are offset by the fact they are too large, resulting in poor exhaust performance and lost power/torque. Some of these negatives can be eliminated by porting the cylinder heads in the manner we have been accustomed to. However, the casting thickness and original shaping imposes limits to what we have been able to do and those limits are significant enough that we no longer care to push them. To port one of these heads takes a number of days and is quite tedious. Just the inlet ports of these heads take over 14 hours of concentrated, careful work. When we are done, the thickness in some areas of the inlet ports is nominally .080” thick and in some cases I’m sure this thickness has been less. Because of the extremely thin final port walls needed for success, there is no tolerance for error, either on the part of the head porter (who must use templates and skill to maintain the proper form and final dimensions) or with the casting (which apparently needs to be as perfect as possible to start with). The exhaust ports only take about 4 hours to port and require only that their short side turns are made round (rather than a sharp 90* angle as with the stock casting) and that the port is generally cleaned up and polished. The chambers take about 6 hours to rework and extreme care has to be taken to maintain what little material is available around the periphery of the inlet valve seat, so that the proper contour can be maintained from the top of the seat, out to the deck. There really is not enough material left from the factory to achieve the results we would desire, but we can get extremely close. The exhaust side of the chamber is poorly machined (for flow purposes) from the factory and there is not much that can be done with it other than to just lay the chamber walls away from the valve to help unshroud them slightly. I’ll also add that the inlet valve job on these heads is extremely critical and requires much more than standard concentric stepped angles. In fact, everything involving the inlet side of these heads is extremely critical to keep the flow “happy” all the way up the valve lift curve. If the inlet ports are not shaped just right, made large enough in the proper areas, or the valve seat/chamber deshrouding form is off, the flow as seen on a flow bench will stop increasing just after .300” lift and then actually go down. This phenomenon is commonly referred to as the port “backing up” and results in the type of power curves we’ve seen on the dyno. As the flow volume goes up, the port reaches a limit of flow and the engine is not able to breath as well as it needs to in order to continue making additional power. Needless to say, the effort and stress of porting one of these heads successfully is enough to hamper any head porters enthusiasm. The time and concentration it takes to do the job right can only be considered worth it, if the end product is reflective of that time and effort. Unfortunately for us, the energy put into these heads always seems to end up greater then the satisfaction gained from the end product. Throw in the gamble of a bad casting and the entire operation begins to seem somewhat futile. As the old adage goes, “you can’t make a silk purse from a sow’s ear” and we couldn’t have said it better ourselves.

Home | Cylinder Heads | Articles ©2008 Sean Brown All rights reserved. |